Image Credit: Canva

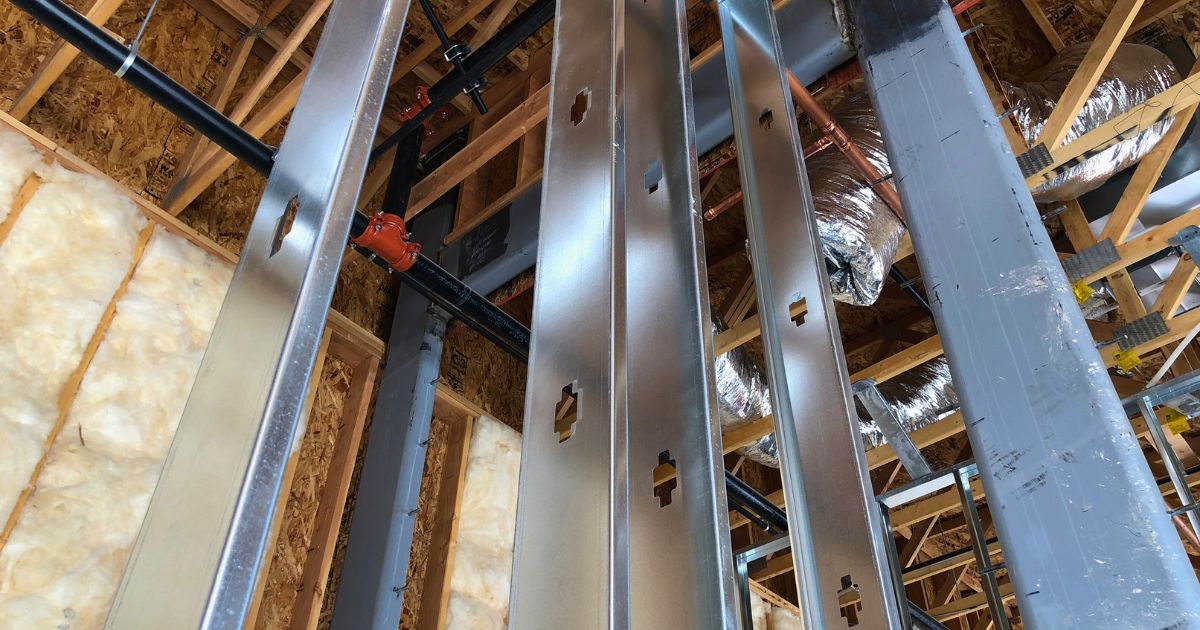

Steel studs are popular in both commercial and residential construction. As a contractor on a remodel project or to install metal studs on new work, you will need to know the proper method for drilling into metal studs. This is different than drilling into wood studs.

With the right tools and a little practice, you’ll be able to do it like a professional. The following instructions show you how to drill holes in metal studs to get the best results.

Benefits of Using Metal Studs

Metal studs are less expensive and lighter than wood studs, and are perfectly straight. They resist fire, insects, and decay, and they’re easy to join, saving both time and money.

- They are lightweight and hollow, making them easy to transport to construction sites.

- They do not require pest control as they are termite resistant.

- They last longer and handle the torque and twisting caused by earthquakes and other natural disasters better than wood.

- They are recyclable and do not contain VOCs, making them environmentally friendly.

Drilling into metal framing members

The need to drill into steel usually comes up when doing remodeling work on new steel-frame construction or a home with metal studs. In the trim phase of new construction work, the same drilling recommendations used for remodeling work should be followed.

Remodeling Work

Locate the studs.

Determine the exact location of the studs using a stud finder. You can download a mobile app that will give it this ability.

The spacing of the metal studs will be 16 or 24 inches on center, depending on whether the framing is load bearing.

You will need to know the exact location of the stud, as metal studs are typically only about 1 1/4 inches wide. Drilling too close to the edge can cause the hole to collapse or failure of the drilled hole. For this reason, mark both sides of the stud to ensure you will be drilling in the center.

2. Use a bit made specifically for steel.

Most drill bits go through steel studs. However, using the wrong bit can damage the bit or create a rough, jagged hole.Today’s Homeowner Tip

Bits made of titanium or cobalt are the best choice for drilling metal. They are often bright gold or silver in color, and can easily pierce steel studs multiple times.

3. Drill at low RPM.

It is better to keep the RPM low when drilling into metal studs, as high RPM will overheat the bit and break it. The ideal RPM range is 700 to 1,000. When drilling into metal studs, it is not a good idea to use a hammer drill, as it can damage the metal.

4. Use the appropriate screws for the job.

You don’t need to drill holes to hang drywall; drywall screws penetrate metal without the need for pilot holes. Hang drywall on steel studs using fine drywall screws rated 20 to 25 gauge. On 12- to 20-gauge studs, use self-drilling drywall screws, which have sharper-than-average tips and thinner threads to avoid splintering the metal and provide better grip than standard threads.

5. Installing the wooden base and cladding.

Baseboard or other wood trim requires pilot holes. Locate the studs, drill only a 1/4-inch countersink hole in the trim. This allows the head of the screw to rest below the surface of the trim. Then run a 1/8-inch bit through the trim alone. Do not drill into the studs. Attach the trim to the drywall and studs using 1 1/2-inch self-drilling trim screws.

New Construction

In addition to the guidelines above, construction of a new building will involve attaching steel to steel. Some fasteners may require pilot holes to be drilled, while others do not. Choosing the right fastener is most important for proper strength.Today’s Homeowner Tip

When attaching steel studs to metal channel, pan head framing screws are the best choice, but many contractors use self-drilling, fine thread, drywall screws.

Regardless of which one you choose, make sure the screw has a pan head, not a bugle head. Bugle head screws will work, but the pan head will lie flat against the metal framing and provide more support. Avoid coarse-threaded screws, as they will pierce through the metal, leaving the hole too large to grip.

When attaching a steel stud channel to concrete flooring, concrete screws work best for this application. These are usually self-tapping and penetrate metal easily, but you must drill a pilot hole into the concrete first.